WarraniumSAF - Submerged Aerated Filter

The WarraniumSAF Submerged Aerated Filter or SAF is a very compact, robust and trouble-free process ideally suited to package type plants for communities and labour camps. The process employs a structured, support media and this forms an ideal place for the biomass to attach itself. The wastewater then passes through the matrix where the biomass consumes the organic matter.

The connections underneath will take you to more information on each of the designs.

The WarraniumSAF media is a non-clogging structure, fixed

set up and with a very high surface area for the volume, it

occupies. It fits fully submerged in the biozone. The water

goes through the cross fluted media in an exact way, flowing

through every part ensuring excellent contact with the

biomass. Air is introduced underneath and the media ensures

very high oxygen transfer rates, allowing for small air blowers

and reduced running costs. After the biozone, a standard

settlement tank is used to elucidate the water of any biomass

that has segregated itself from the support grid. The is no

requirement for a sludge recirculation system.

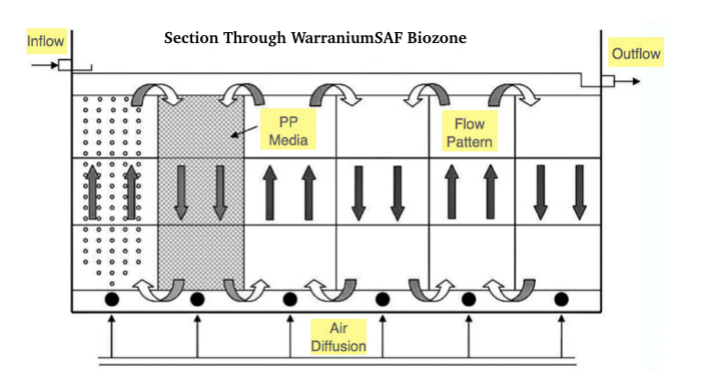

WarraniumSAF Biozone Flow Pattern - Cross-section

schematic showing the water flow pattern within the biozone.

The careful placement of the air sparge pipes supply the

diffused air with a very high oxygen transfer efficiency, close

to fine bubble air diffusion system. Above the air sparge pipes,

the water flow is ‘air-lifted’ and then allowed to gravitate

down, causing a circular, fully mixed flow within the biozone.

The water flow pattern provides excellent contact between the

water and its nutrients and the biomass attached to the media.

A further benefit is a very long sludge age, partial de-

nitrification, low sludge production and low energy

consumption.

WarraniumSAF Biozone Flow Pattern - Cross-section

schematic showing the water flow pattern within the biozone.

The careful placement of the air sparge pipes supply the

diffused air with a very high oxygen transfer efficiency, close

to fine bubble air diffusion system. Above the air sparge pipes,

the water flow is ‘air-lifted’ and then allowed to gravitate

down, causing a circular, fully mixed flow within the biozone.

The water flow pattern provides excellent contact between the

water and its nutrients and the biomass attached to the media.

A further benefit is a very long sludge age, partial de-

nitrification, low sludge production and low energy

consumption.

The plant does not need constant operator attention and is

happy to run in automatic mode for extended periods.

WarraniumSAF plants deliver a very high quality of effluent to

meet the highest standards specified, including a fully nitrified

Treated Sewage Effluent (TSE). The WarraniumSAF attached

growth technology can be added to existing plants to upgrade

the final effluent, in particular for plants suffering high

ammonia levels in their effluent. Often the WarraniumSAF

Biozone, dedicated to ammonia removal is sufficient but in

other cases, a further settlement tank will be needed.

For complete de-nitrification the Warranium submerged,

attached growth technology used in the WarraniumSAF is

modified to an anaerobic process call the WarraniumSNAF

(Submerged Non-Aerobic Filter). With hydraulic circulation,

nutrient and alkalinity dosing, the effluent can be fully de-

nitrified in cases where nitrates would be unacceptable in the

receiving waters.

Warranium Energy has standardised WarraniumSAF plants

which are ISO Container sized for easy, worldwide shipping.

The capacities of these standardised plants are: 50 m3 per day

up to 1000 m3 per day all with tertiary treatment giving an

effluent quality of 10 mg/l BOD and 10 mg/l suspended

solids. These can serve 250 persons - 5,000 persons.

Larger sizes are individually sized and manufactured up to

municipal sized plants with either steel fabricated tanks or

locally constructed concrete tanks.

The WarraniumSAF process is ideal for upgrading and

increasing the capacity of existing treatment works by utilising

the tank work in place. Below is a photo of an old activated

sludge plant having its aeration tank upgraded with Modular

WarraniumSAF technology. All prefabricated and factory

tested for rapid installation and minimal disruption.

WarraniumSAF plants are often in stock for immediate

despatch worldwide.